This potato chips production line is suitable for different variety of snack chips such as : potato chips,wave chips,cassava chips etc.

1. Different Choice For Customer Reference

A. Full Automatic Potato Chips Production Line

---Capacity : 100kg/hr,150kg/hr,200kg/hr,260kg/hr, 300kg/hr,400kg/hr,500kg/hr

---Advantages :

★ Continuously working with elevating and conveyor

★ More labor saving and easy operation

★ 4-6 working people enough

★ Big capacity with higher investment return

★ Totally 14 machines

---Applications : Suitable for big and medium scale investment with enough space for workshop and with enough investment funds. etc.

B. Semi Automatic Potato Chips Production Line

---Capacity : 50kg/hr,100kg/hr,150kg/hr,200kg/hr

---Advantages :

★ Small land area needed

★ Lower power consumption

★ 6-8 working people enough

★ No need installation at customer workshop

★ Totall 8 machines

---Applications : Mainly suitable for small scale investment such as grocery,retail store, supermarket,restaurant,canteen etc.

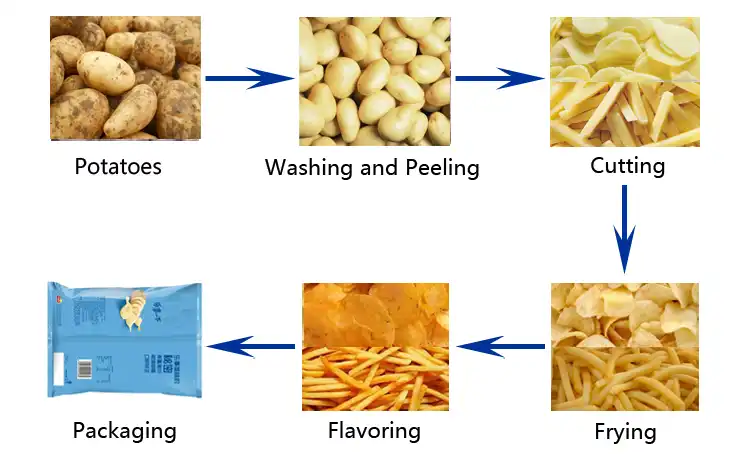

2. Working Flows Of Potato Chips Making Machines

A. Automatic Potato Chips Produciton line --- Capacity 100kg/hr hour for your reference

| NO. | Product Name | Voltage/Power | Overall Dimension | General Description |

1 | Loading Elevator | 380V/0.37kw | 2500*700*2200mm | Load and send the potatoes into next machine |

2 | Washing & Peeling Machine | 380V/2.75kw | 2835*700*1460mm | Wash and peel the potatoes |

3 | Sorting Conveyor Belt | 380V/0.37kw | 3000*740*1100mm | Pick out the potaoes with worm hole |

4 | Loading Elevator | 380V/0.37kw | 1700*700*1600mm | Transmit potatoes into the next machine |

5 | Cutting Machine | 380V/0.75kw | 745*590*1385mm | Cutting potatoes in customized size |

6 | Bubble Washing Machine | 380V/1.87kw | 2500*1010*1250mm | Wash off extra starch on the surface of potato chips |

7 | Blanching Machine | 380V/54.37kw | 4000*1000*1200mm | To inhibit the activity of the enzymes and protect color |

8 | Cooling Machine | 380V/1.87kw | 2500*1010*1250mm | Cool down the temperature,avoid potato chips stick together |

| 9 | Dewatering Machine | 380V/6.0kw | 4000*950*1600mm | Remove water moisture, prepared for the frying part. |

| 10 | Frying Machine | 380V/127kw | 5000*1350*2250mm | Set the suitable frying temperature and time to get the best quality of potato chips |

| 11 | De-Oiling Machine | 380V/6.0kw | 4000*950*1600mm | Remove extra oil on the surface of potato chips |

| 12 | Picking Belt | 380V/1.12kw | 2800*850*2200mm | Pick out the bad potato chips and convey evenly to the next machine |

| 13 | Flavoring Machine | 380V/5.25kw | 4000*2000*4300mm | Add different powder flavors evenly |

| 16 | Packing Mahcine | 380V/0.75kw | 2800*1050*2500mm | Automatic weighting,packing&sealing with customized bag size and weight accordingly |

B. Semi-automatic Potato Chips Production Line (Without elevator and conveyor belt) ---Capacity 200kg per hour for your reference

NO. | Product Name | Voltage/Power | Overall Dimension | General Description |

1 | Washing and Peeling Machine | 380V/1.1kw | 1600*730*840mm | Wash and peel the potaoes |

2 | Cutting Machine | 380V/0.75kw | 730*590*920mm | Cutting potatoes into potato chips |

3 | Blanching Machine | 380V/27kw | 1600*1050*1100mm | To inhibit the activity of the enzymes and protect color |

4 | De-watering Machine | 380V/1.1kw | 1020*620*900mm | Remove water moisture, prepared for the frying part. |

5 | Frying Machine | 380V/54kw | 2350*1050*1200mm | Set the suitable frying temperature and time to get the best quality of potato chips |

6 | De-oiling Machine | 380V/1.1kw | 1020*620*900mm | Remove extra oil on the surface |

7 | Flavoring Machine | 380V/0.75kw | 1000*800*1380mm | Add different flavors powder evenly and uniformly |

8 | Packing Machine | 380V/2 kw | 1220*680*900mm | Packing sealing with customized bag size and weight |